Since extending the Z-axis on my wanhao i3 printer I discovered that there was a small amount of ringing toward the middle of the axis when printing at high speeds. To alleviate this I decided to use the feed screw to provide extra support.

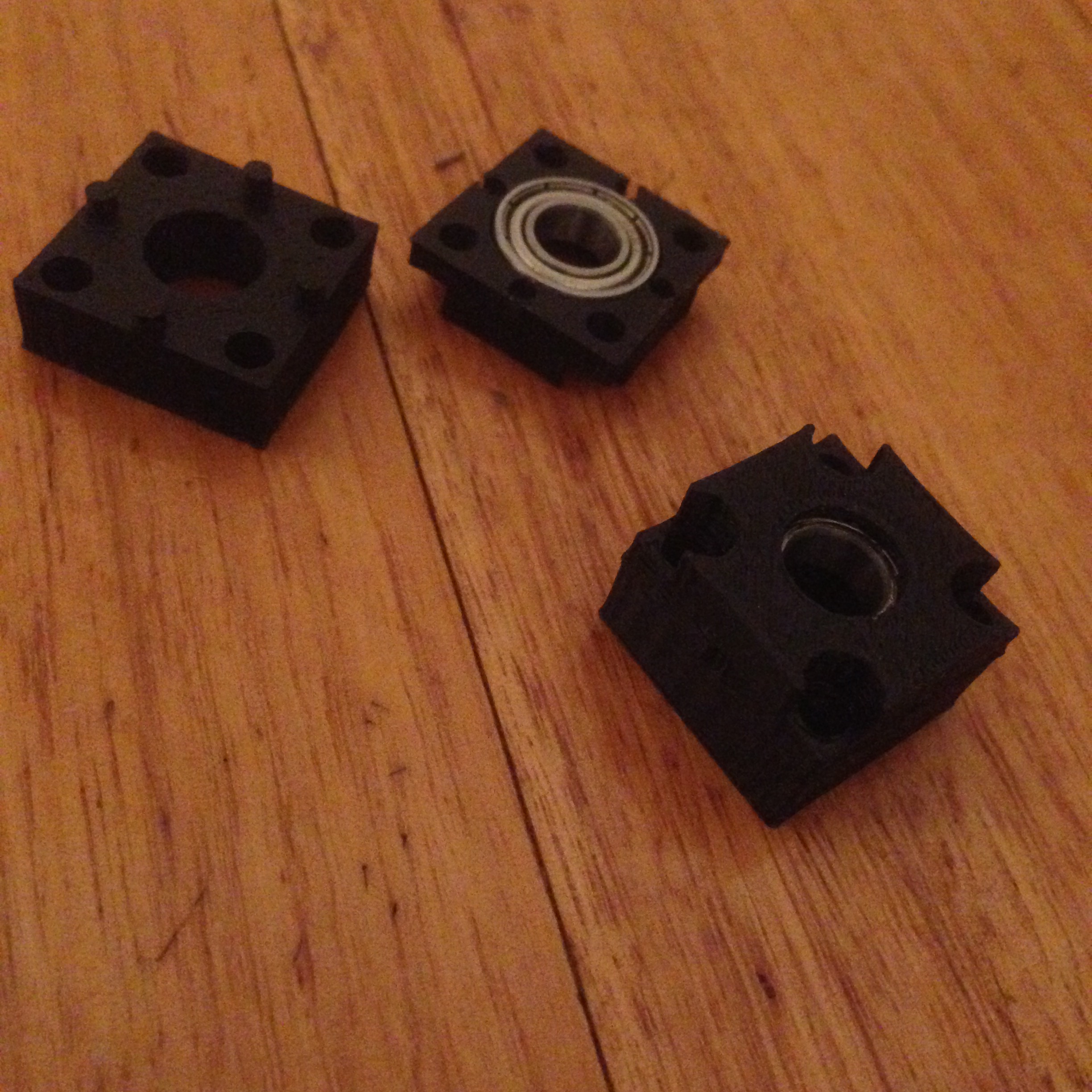

I did this by putting a small bearing block at the top of the axis. However for this to work you will want to check that your feed screws are perfectly straight, this is easily done by putting it against the straight edge of a ruler or on a piece of glass. The bearings for the block are 8mm ID x 16mm OD x 5mm Wide MR688ZZ. These should be available online from most hobby stores as they are fitted to many model helicopters.

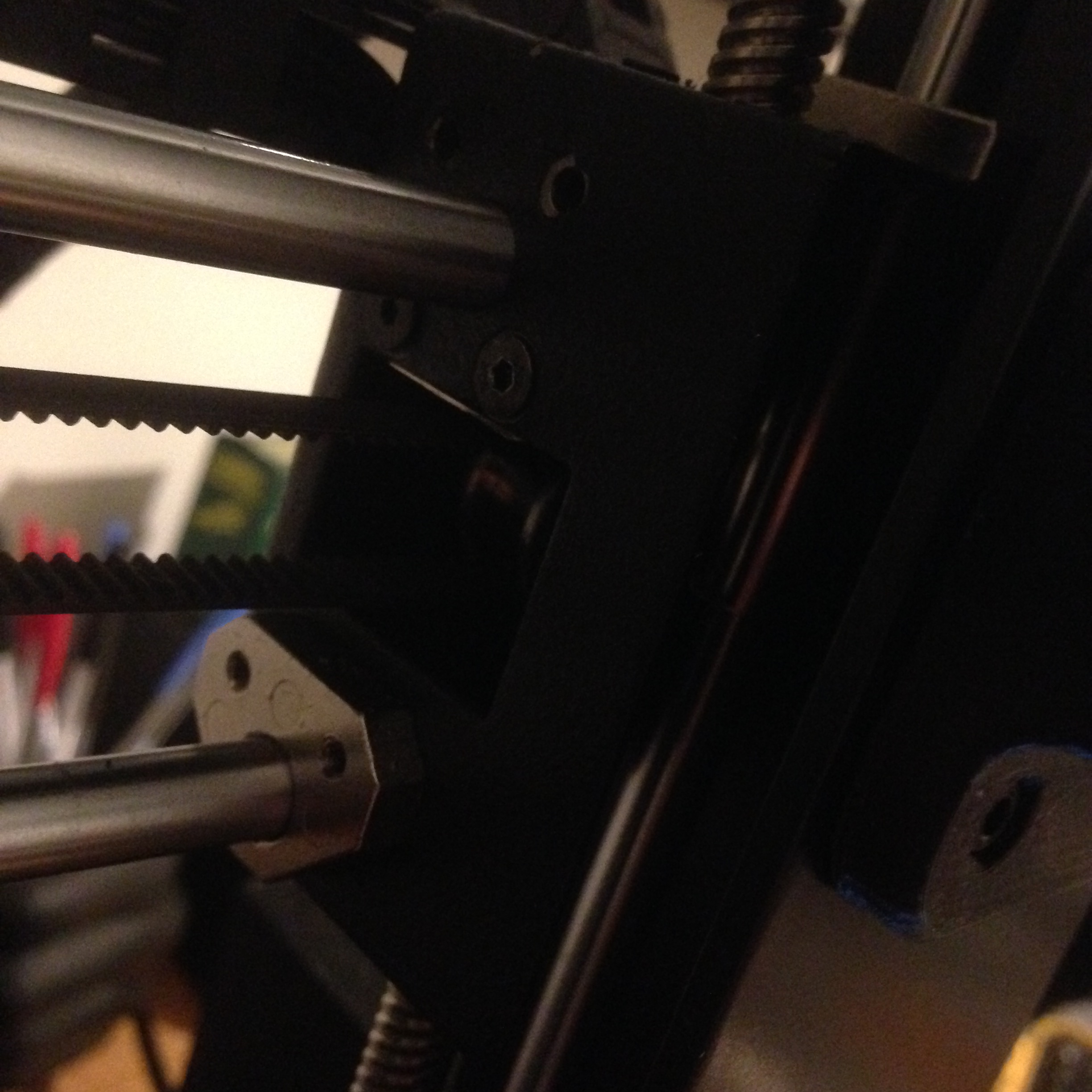

While doing this modification I also moved the X-axis bearing rod holders to the outside of the carrier, this was to make it simpler to tighten the locking grubscrews, and to allow me to invert the Z-axis nuts. By putting the Z-axis nuts inside the carrier it was possible to conserve height. I turned one of the bearing rod holders upside down and countersunk the heads of the screws, this freed up an extra 4mm of travel on the X-axis.

To mount the bearing blocks you will want to extend the X-gantry up so that only 10mm or so of the feed screw is protruding. Fit the bearing block over the feed screw, then place the top plate with the bearing rod holder on top, this will align everything nice and parallel. I used a little bit of hot glue to hold the bearing block onto the top plate so that I could mark the position for the screw holes. Using a 3.5mm drill make the four holes in each plate, then using 15mm M3 bolts and matching M3 nuts lightly bolt the bearing blocks to the top plate. Fit the plate with bearing block back over the bearing rod and feed screw before tightening the bolts up, this will make sure that everything is perfectly aligned.

It’s simply a matter of bolting the top back onto the printer and checking that the Z-axis moves up and down freely without any resistance.

As always here are the STL files